O Rings

Introduction

Manufacturer of standard and custom rubber & TPV/TPE O-rings to your specification. Rubber O-Rings can be manufactured from a wide range of elastomers and thermoplastic vulcanizate materials to suit many applications including. Marine, Aerospace, Automotive, and General industry. Many of which expose our custom seals and O-rings to harsh environments and mission-critical conditions.

In the fabrication process, the seals used may require the capability to withstand extreme pressures within hydraulic presses and/or high chemical resistance to caustic fluids in pumps

Product Description:

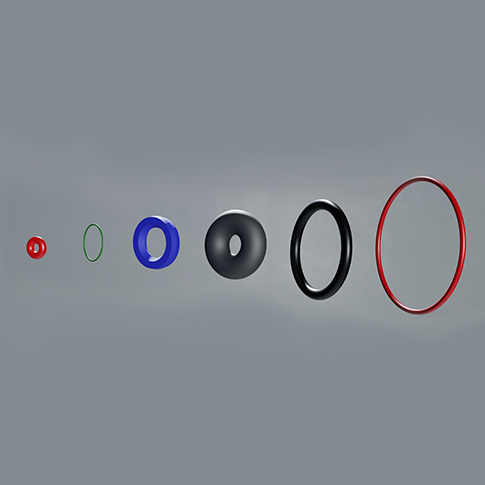

The international standard ISO 3601 has a comprehensive list of standard O-Rings. We manufacture these O Rings from a variety of materials to meet your requirements and industry standards. Typical elastomers and TPE that we manufacture O-Rings include Silicone, Flurosilicone, EPDM, FKM, Neoprene, Nitrile (Buna-N), NBR, HNBR, Sanroprene and many more standard and custom formulated compounds.

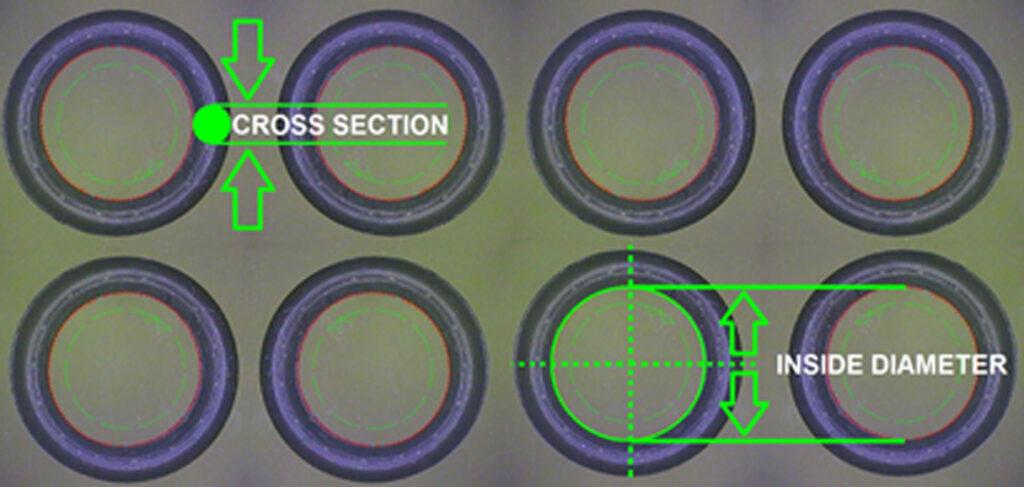

Please note that each elastomer material shrinks at a different rate & so the tooling used to manufacture an ISO 3601 Nitrile-70 O-Ring will not be suitable for manufacturing an O-Ring in a different material. For example, most Nitrile-70’ shrink at 1.8% & most of our Silicones shrinks at 3-4% during the manufacturing process. As a result, we have custom-sized O-Ring tools (dies and molds) for each elastomer material to allow for shrinkage compensation. This method allows us to always provide the best quality O rings to our customers.

Custom O Rings Specification

Type of Custom O Rings

Quadra Seals

Custom Cross Rings & Quadra Seals

As a bespoke rubber manufacturer, we can supply X Rings, Quad Seals, V seal etc custom shapes in an extensive range of commercial grade rubbers and TPVs. X Rings are often used in low pressure or low temperature environments where a high-quality seal is still required. We have supplied X Rings and Quad seals to a great deal of industries including aerospace and automotive companies.

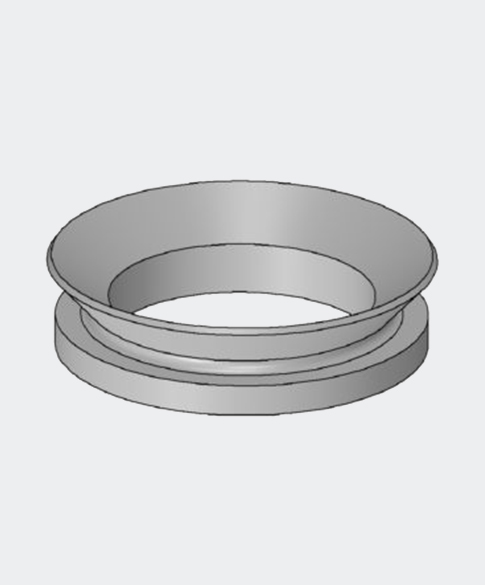

Custom Layered O Rings

We are a manufacturer and supplier of custom triple O ring seals to an array of industries including Automotive, Aerospace, Food & Dairy, Renewable energy, and Marine sectors to name a few. We can supply Triple O Ring seals in almost any elastomer material from our wide range of rubbers. Seals can be made as fully molded rings, extrusions for endless joining for more complex shapes and profiles.

Custom V Seals & V Rings

We also make custom rubber injection and compression moulded V Seals. We supply V Seals to many of the leading companies in industries such as Aerospace, Automotive, Pharmaceuticals, and Marine. V Seals are primarily used as axial shaft seals however they can have many applications, we can also manufacture V Seal extrusions as opposed to rings. Rubber moulded seals can be manufactured in Rubber or Silicone selected from our extensive range of commercial grade materials designed to meet your project’s needs.

Custom Rubber Wiper Seals

Wiper and scraper seals are used as an axial seal for a rotary shaft with the added benefit of allowing the shaft to reciprocate back and forth. We are proud suppliers of custom rubber wiper and scraper seals to large industrial, Automotive and Food & Drink companies. Seals can be manufactured in almost any rubber or silicone from our extensive range of commercial grade materials. We produce rubber seals as rings, extrusions or other more bespoke shapes.

Custom U Section Seal

We can supply U Section Seals in almost any material from our wide range of rubbers (Silicone, EPDM, Nitrile, FKM, Santoprene) in stock. Seals can be made as fully molded rings, or extrusions for more complex shapes that will joined to make endless rings.